The G40, G41, G42 codes do tool radius offsetting. After an incedent where my machine somehow lost it's position, machining a load of parts with a 1.5mm x,y error, I wondered how easy it is to add absolute encoders to it.

#Cambam move absolute code#

When writing code by hand these things kept you from going completely mad as the code that would replace them would be thousands of lines. I have a DIY gantry machine and I have a stack of resolver position sensors (contactless rotary encoder 4096 steps per rev). Then there were G70-G79 range cycles for things like circular pockets, rectangular pockets, mirroring, rotation about an axis and such. The other space and programmer saving things were canned cycles, like G80,G81,G82, which were drilling cycles that did depth,peck, chip break and such. This is harmless if your Mach3 defaults are set for Absolute Distance Mode and Incremental IJ. Mach3 ignores the G90 and only accepts G91.1.

4 digital numeric displays, X,Y,Z and G-code or M-Code number and some red lights indicating G, M, F etc. Note 1: My configuration of CamBam puts G90 and G91.1 on the same line. Modality saves memory, lots of CNCs work fine without line numbers too.

#Cambam move absolute professional#

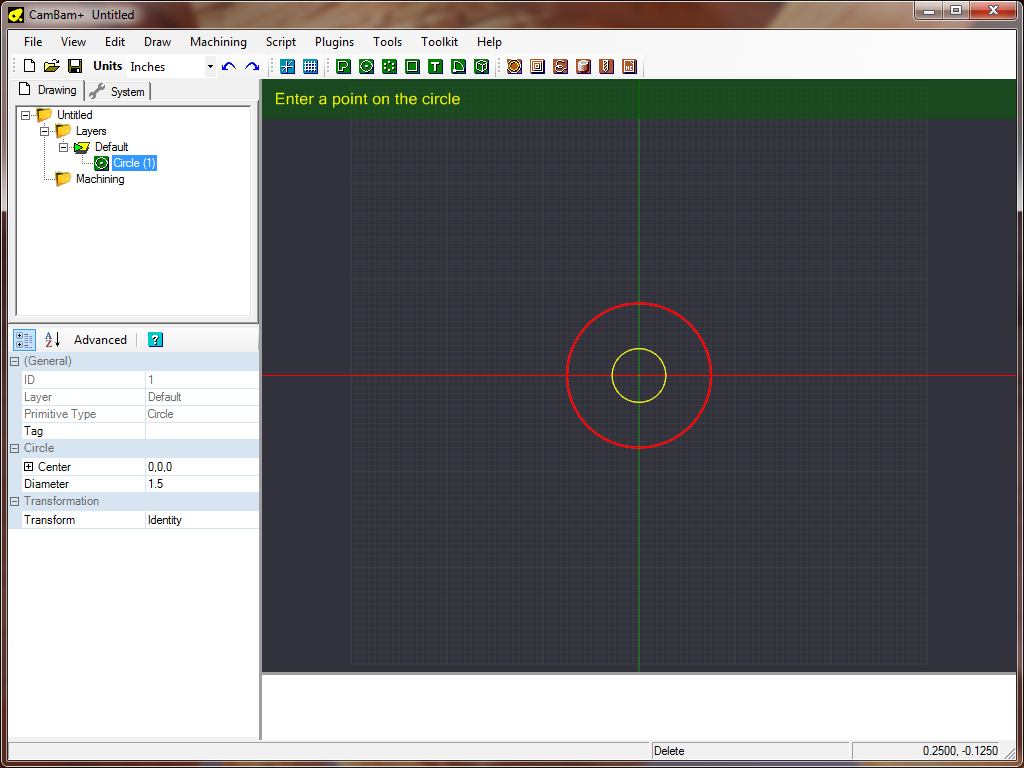

CamBam has many users worldwide, from CNC hobbyists to professional machinists and engineers. Lots of G-code stuff comes from the old paper tape days, and then really underpowered CNC controllers. CamBam is an application to create CAM files (gcode) from CAD source files or its own internal geometry editor. Works quite well except all programming is G-code only. 3 axis of control to move from a drain port to each tube and a 4th axis running a peristaltic pump to pull the sample and accurately dispense into the test tubes. I modeled the rack in SolidWorks, programmed the shop CNC using CamBam to cut out the 144 holes and then imported the same geometry into a cheap TopCNC TC55H CNC controller. I've argued that that is the safe and correct way to do it, as the clearance plane means just that, a Z height where it is safe to move in X and Y. He doesn't think this is right because if the tool is way up high it rapids Down to the Clearance plane. It also controls printer bed temperature and extruder head temperature.Ī couple of weeks back I bought a Chinese 3020 router and built a test tube rack for it. CamBam on the other hand does a Z move to the Clearance plane before any X or Y move. A DL06 handles all the button functions, switches between the R8 spindle, router spindle, lathe spindle and 3D printer extruder. I built my own 4 axis CNC in my garage running on Mach 3 with a motion card. I am currently active on the Practical Machinist, Mach 3, Home Shop Machinist, CamBam, and Reprap forums, worked as CNC programmer, bought the CNC in our shop. Quote from: Garyhlucas on December 27, 2016, 09:02:11 PM I think I have a little experience at this level of discussion.

0 kommentar(er)

0 kommentar(er)